Oil & Gas

Disc Springs for Oil Industry

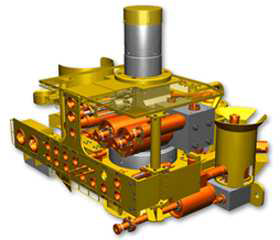

Subsea Valves & Actuators

More than 9000 spring stacks for large valve actuators.

Over 100,000 springs for small valve actuators.

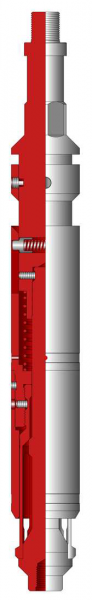

More than 125 stacks for landing strings.

Hundreds of large Inconel springs for sub-surface valves.

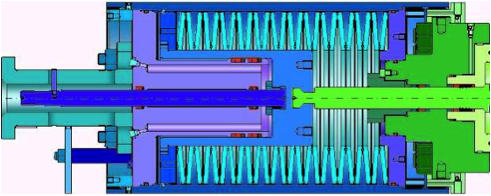

Control & Safety Valve Actuators for Deepwater Subsea

Trees, Manifolds & Jumpers

Surface Gate Valves, Control Valves, & Safety Valves

Wireline equipment

Drilling Motors, Turbines, Jars, Shock & Fishing Tools, Downhole

Safety Brakes for Drawworks, Mobile & Drilling Rigs, Winches, Hose Reel Stations, Capillary Injector Heads, Cable Spooling Units

Disc Spring Stacks vs. Coil Springs

- High spring load with small spring deflection

- Better space utilization than with other spring types

- High fatigue life and low creep tendency with correct dimensioning

- Disc springs allow nearly any kind of characteristic curve

- Modular construction: Different combinations of disc springs show different characteristic curves including parallel stack and series stack

Advantages of China Disc Springs, Inc.

- Engineering & designing assistance

- Raw material from own cold rolling mill up to 6mm

- Own tooling shop

- Complete inhouse-production from raw material to finished disc spring

- Shot peening as a standard process for increased fatigue life

- Customer oriented service (e.g. stack pre-assembling)

- Special material for specific applications

- Various protective coating

- Own test laboratory

- Self-centering stacks do not need any additional guiding. They reduce friction and are applicable for disc spring dimensions greater than 200 mm OD