EN 16983 (DIN 2093) Disc Spring Classification

Classification according to EN 16983 (DIN 2093)

China Disc Springs, Inc. have been designed and manufactured according to EN 16983 (previously known as DIN 2093) (Disc springs, Calculation, Dimensions, Quality requirements). Standard EN 16983 (DIN 2093) disc springs are classified into 3 groups:

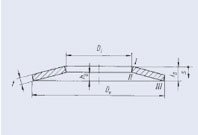

- Group 1: Disc thickness, t, less than 1.25 mm (Manufactured without contact surfaces)

- Group 2: Disc thickness, t, from 1.25 mm to 6 mm (Manufactured without contact surfaces)

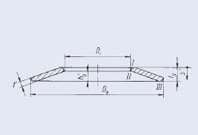

- Group 3: Disc thickness, t, over 6 mm up to 14 mm (Manufactured with contact surfaces)

Group 1 and 2 springs without contact surfaces

Group 3 springs with contact surfaces

EN 16983 (DIN 2093) Spring Requirements

| Group | Production Method | Surface Finish**) | |

|---|---|---|---|

| Upper and lower surfaces u | Inner and outer edges u | ||

| 1 | stamped, cold-formed, edges rounded | R2 < 3.2 | R2 < 12.5 |

| 2*) | stamped, cold-formed, De and Di turned, edges rounded | R2 < 6.3 | R2 < 6.3 |

| fine-blanked, cold-formed, edges rounded | R2 < 6.3 | R2 < 3.2 | |

| 3 | cold- or hot-formed, turned on all sides, edges rounded | R2 < 12.5 | R2 < 12.5 |

| *) Unless otherwise specified, the manufacturing process is left to the discretion of the manufacturer (see Section 5 in EN 16983). **) The specified values do not apply to shot-peened disc springs. | |||

Other production methods, such as laser-beam cutting or water-jet cutting etc., may be used for the production of special disc springs. In addition to disc springs with a rectangular cross-section and rounded edges, there are the following types:

- Disc springs with a trapezoidal cross-section

- Disc springs with slots