Production

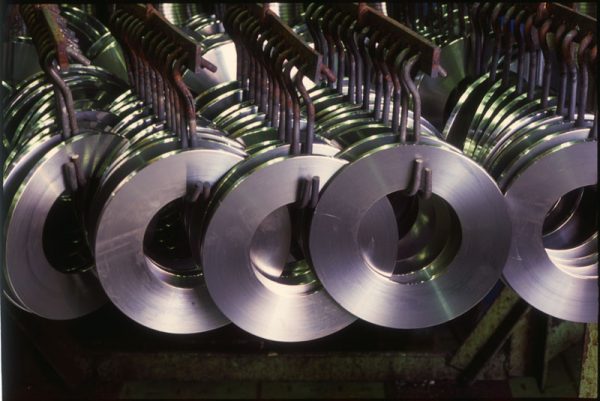

In the manufacturing of Belleville disc springs, China Disc Springs sets high internal standards to ensure superior quality at a reasonable cost by using innovative and extremely efficient production methods, starting with the production of the raw material.

In the manufacturing of Belleville disc springs, China Disc Springs sets high internal standards to ensure superior quality at a reasonable cost by using innovative and extremely efficient production methods, starting with the production of the raw material.

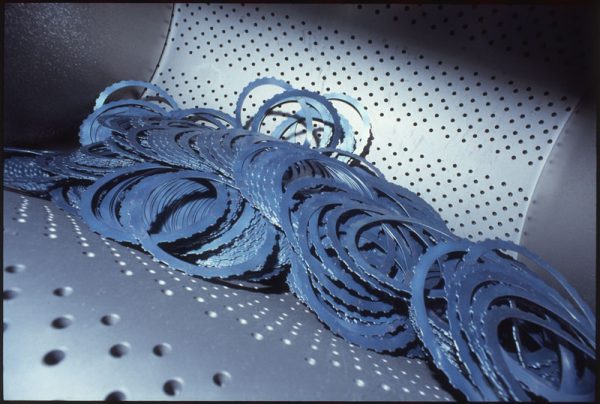

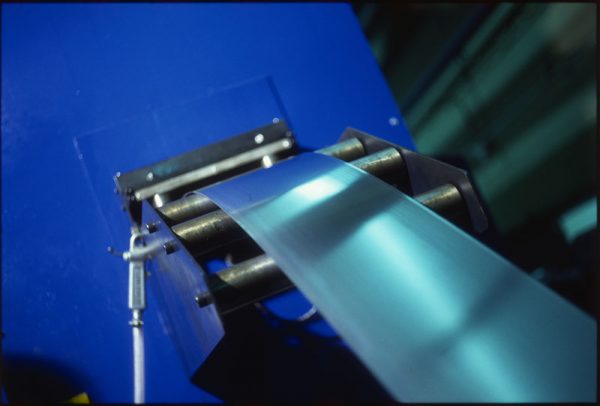

The majority of strip material used is produced to very tight tolerances. Depending on the disc thickness, the disc blanks are manufactured by stamping (Group 1), fine blanking (Group 2) or plasma arc/flame cutting (Group 3). Disc springs of greater material thickness are machined all over to remove surface imperfections. Depending on the application, disc springs can be heat treated with either a martempering or austempering process to extremely tight hardness tolerances. Subsequent shot-peening improves the fatigue life of the springs. Our standard corrosion protection, phosphating and oiling, is done in our own facility. Complete monitoring of the various production stages guarantees the high quality of China Disc Springs, Inc.. China Disc Springs’s quality system is certified to ISO/TS 16949 standards.