Machine Tool

Tool Clamping Components

China Disc Springs manufactures disc spring tool clamping components. The tool is released by a hydraulically operated piston, which slides forward over a bolt and clamping tool. As the spring stack is compressed, the collet opens simultaneously. The clamping of the tool is activated by the spring stack. Reduction of hydraulic pressure causes stack unloading and the tool moves into the spindle. The stack of disc springs lock the tool in a clamped position.

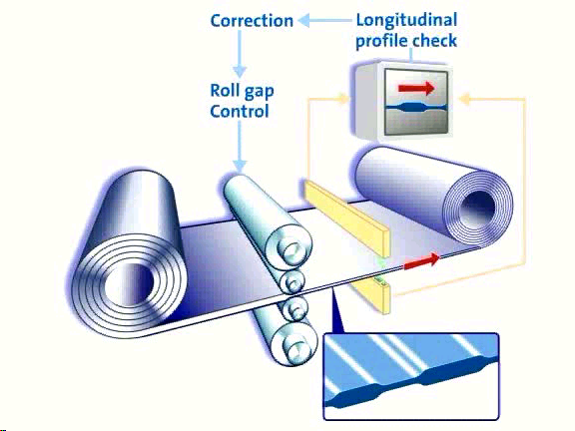

Roller Spring Suspension

The rollers are held at a specific force by a stack of disc springs. Upon an extreme change in raw material thickness or foreign material passing through the rollers, the disc springs allow the rollers to flex. This avoids damage to the rollers and bearings.

Punching Dies

The springs are installed as stacks under the ejection plates in die-cutting and fine cutting tools. When the upper and lower tools come together (during cutting) the ejection plate is pressed down, compressing the spring stacks. After the completion of the cutting process, the die plate is brought back to starting position by the spring stacks.